Bespoke

If you're looking for your dream handbag or other leather accessory, you've come to the right place!

The price of custom production depends on the complexity of the product development, the intricacy of the pattern, the level of craftsmanship and, last but not least, the price and quantity of materials used, including those for the production of the prototype.

Thanks to the in-house production combined with direct sales to end customers, I can afford to include in the final price only the actual expenses incurred, which for the most part are hours of my meticulous work. It is not a written rule that the bigger the handbag, the more expensive it will be.

DESIGN

The first step on the path to your dream handbag is an idea of what it should look like and what function it should fulfill. Before you start thinking, ask yourself two questions:

What must fit in the handbag? Wallet, mobile phone, keys, glasses, diary, water bottle, laptop, tablet, folding umbrella, …

Where will I wear it? To work, to the city, or everywhere with me?

Keep in mind that large leather handbags can hold a lot of things, but they can weigh up to one kilogram when empty. Think carefully about how many pockets and compartments you need so that you can always quickly find what you are looking for.

PATTERN

The creation of a pattern according to the design and dimensions of the handbag is the most important stage of development, from which all subsequent actions depend. If the pattern is not flawlessly technologically processed, the flaws can be eliminated in the prototype phase, which is created especially for this purpose.

PROTOTYPE

The key moment is the prototype production phase, when the two-dimensional pattern becomes a 3D object and the handbag finally takes its shape.

I sew the complete prototype, i.e. with the lining, internal compartments and pockets, so that the handbag can be tried on at a stage when it is still possible to intervene in the design and adjust the details. However, every slightest change means modifying the already finished paper pattern. The entire pattern must be redone if, for example, we want to dramatically change the proportions of the handbag or the sewing technique. Sometimes it is therefore necessary to create a second prototype.

If we are satisfied with the prototype, we can move on to the next stage of the leather handbag manufacturing process.

PATTERN TRANSFER ONTO LEATHER

The actual cutting of the parts is preceded by an ingeniously thought-out "Tetris game". Each leather is unique. It has an irregular shape and structure, minor natural imperfections can occur on its surface, such as small scars that arose during the animal's lifetime. Sometimes, however, mechanical manufacturing defects appear on the leather, which should be avoided. When searching for the ideal variant for the placement of all parts, I always try to make the most of each leather and not to waste this wonderful material unnecessarily.

LEATHER CUTTING

The most physically demanding phase of the leather handbag manufacturing process is cutting the leather with a sharp scalpel. You simply cannot cut two millimeters thick, strong leather with scissors. In order for all parts to fit together perfectly, a precise, straight cut is required.

PREPARATION

The cut parts are further adjusted as needed on special machines, which, however, deform the leather at the same time, thus causing it to stretch. Therefore, the parts must be cut again to the desired shape.

EDGE PAINTING

A special color is applied to the edges of the individual leather parts before they are sewn to the lining. I mix the paint according to the color design of the handbag in the desired shade directly in the atelier.

There are no limits to imagination. The color of the edges in combination with the same shade of stitching can sophisticatedly transform the look of a plain handbag and perfectly frame its shape.

If you like bold colors, but want a universal yet original black handbag, how about painting its edges with your favorite color shade?

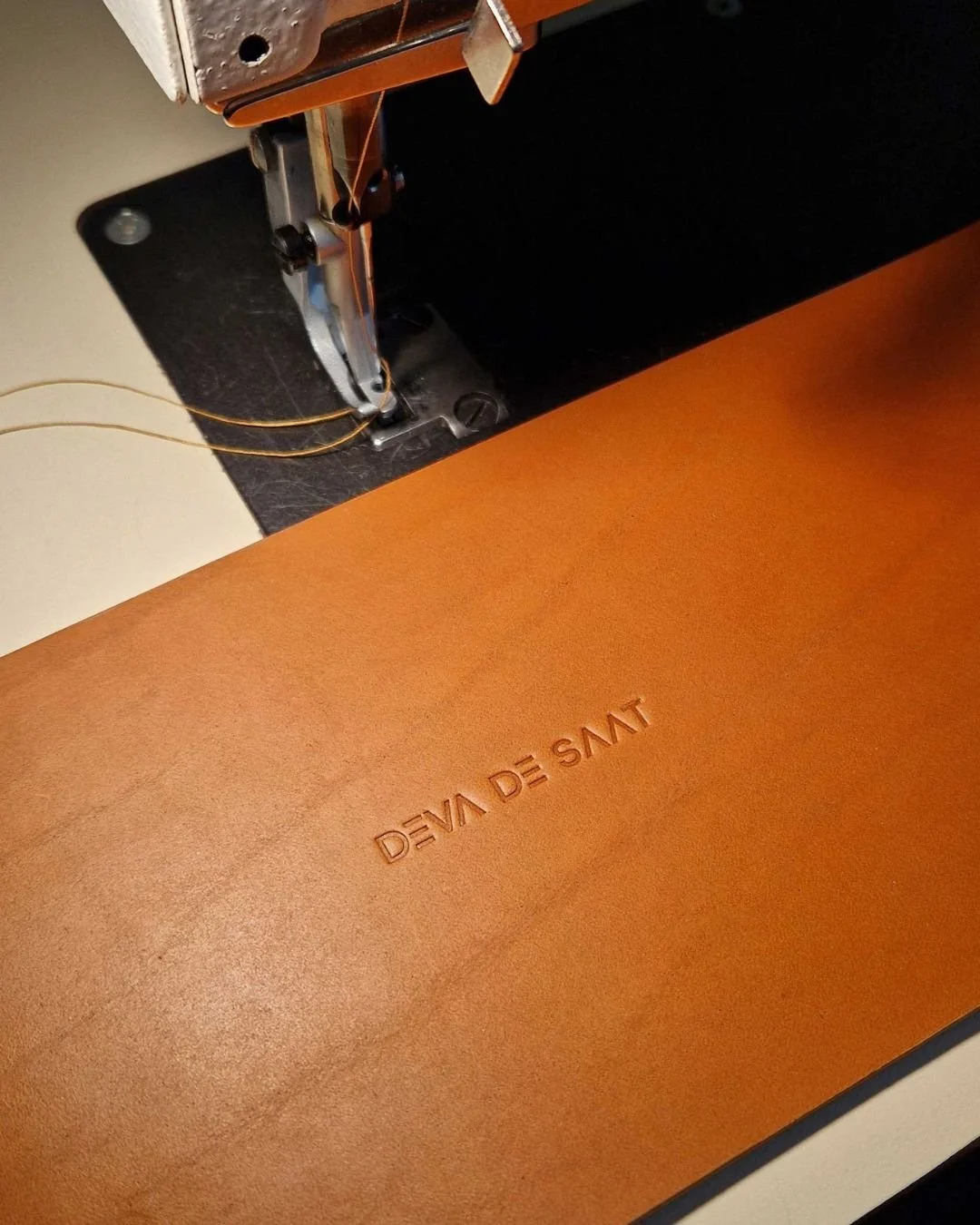

LOGO DEBOSSING

Before I proceed to connect the leather parts with the lining, I emboss the brand logo into the leather. Upon request, it is also possible to emboss your initials. I emboss the monogram on a leather triangle sewn inside the handbag on the lining under the DEVA DE SAAT logo.

LINING

Just like a beautiful woman, a handbag should be beautiful not only on the outside, but also on the inside. When you open the bag and look inside, you will see its beautiful interior, elaborated to the last detail.

The lining is cut from exceptionally durable Japanese Ultrasuede® microfiber, made by the inventor of the world's first ultra-microfiber. It combines the beauty and softness of the finest brushed leather with the unsurpassed performance of man-made material. It is luxurious, modern and elegant.

GLUING

The prepared leather parts are glued to the lining and sewn.

ZIPPER PREPARATION

If the handbag has an inner zip pocket, at this moment it is time to prepare the zipper in the desired length.

For the production of leather handbags and accessories, I use high-quality Excella® brass zippers from the Japanese brand YKK. The length of individual zippers depends on the size of the handbag, which also determines the maximum size of the inner pockets. For this reason, I make the zippers in the desired length directly in the atelier.

SEWING MACHINE

Before I sit down at the sewing machine and start sewing, I have to choose the right needle thickness, the strength and tension of the upper and lower threads, so that the final result is as close to perfection as possible. There is nothing worse than oversized needle holes that are stitched with thin thread - perhaps a minor detail to some, a job poorly done to an experienced eye. The correct combination of needle and thread size is therefore key. In this industry, details really matter and mistakes are not desirable. Just one stitch where it shouldn't be, and you can discard the piece. Leather is unforgiving and the needle hole cannot be undone. Precision and patience are indispensable in this field.

SEWING

At this stage of the leather handbag manufacturing process, the parts are sewn together, the prepared zippers are sewn into the pockets, and the inner leather parts are sewn to the lining.

ASSEMBLY

Step by step, from the sewing machine to the table and back, I gradually complete the individual parts of the handbag.

PRECISION CRAFTSMANSHIP

Slowly but surely, and with millimeter precision, a leather piece is created under the hands of a single woman, for whom the design and development of the product is as important as its quality craftsmanship.

QUALITY CONTROL

Thanks to mastering all the professions of the entire manufacturing process, from the initial design to the final product, I have absolute control over every stage of production of each handbag and accessory.

KNOW-HOW

For my creative work as a designer, I do not need an external company to ensure the development of my designs, nor a workshop to produce my handbags, nor even a merchant to mediate sales.

I will design and handcraft a DEVA DE SAAT handbag for you, and hand it over to you personally or send it to your address. The price of a custom-made handbag therefore reflects only my know-how, time and material.

MAKE YOUR DREAM COME TRUE

If you have an idea of what your dream handbag should look like and you are interested in its approximate price, do not hesitate to send me an email or to call me. The price of the bespoke order is always individual.